How Xentara integrates traditional control technologies with AI, augmented reality, and cloud computing

The article explores the challenges and opportunities in bridging the gap between Operational Technology (OT) and Information Technology (IT) in mechanical engineering environments. While IT systems evolve rapidly, many OT control systems remain outdated, creating integration issues despite the availability of standard interfaces like OPC UA. The concept of “IoT readiness” highlights the need for machines to connect with modern digital infrastructures. Xentara is presented as a real-time middleware platform that enables OT-IT convergence through a semantic data model and modular skills that collect, process, and integrate machine data into higher-level IT systems. Its core innovation lies in a timing model that orchestrates sequential and parallel processing with microsecond precision, supporting advanced features like machine learning integration and control logic synchronization. The platform supports multicore edge controllers, virtual development tools, and flexible connectivity options, enhancing software quality and development speed. Xentara also facilitates retrofit solutions for legacy machines and enables business models focused on value-added services, such as Augmented Reality (AR) for training and operation. Ultimately, it transforms machines into adaptable, IoT-ready platforms that enhance competitiveness and customer value.

Most mechanical engineering organizations have made no substantial change to their existing OT (Operational Technology) control systems. In contrast, IT systems are fast evolving, yet they frequently struggle to connect with these machines. Even standard interfaces such as OPC UA are not widely adopted, making integration into a digitalized plant practically impossible. "IoT readiness" refers to the necessity to connect machines to the future world—a problem but also a huge opportunity. A real-time middleware with OT and IT capabilities is an ideal solution.

Currently, data from PLCs is usually always given only through an OPC UA server. However, existing control hardware is frequently insufficiently powerful, and customized integration into customer-specific communication methods is usually not possible. A real-time OT-IT convergence platform may interact synchronously with current control systems, process data, and integrate easily into higher-level IT structures.

The Xentara platform is primarily composed of a semantic information and data model that controls all current process data. Skills, or expandable I/O functions and communication protocols, collect raw data and send it to microservices, which can be PLC logic, C++ programs, simulation models, or machine learning algorithms. Before the data is transformed into a digital twin for IT systems, additional properties are added.

Timing Model

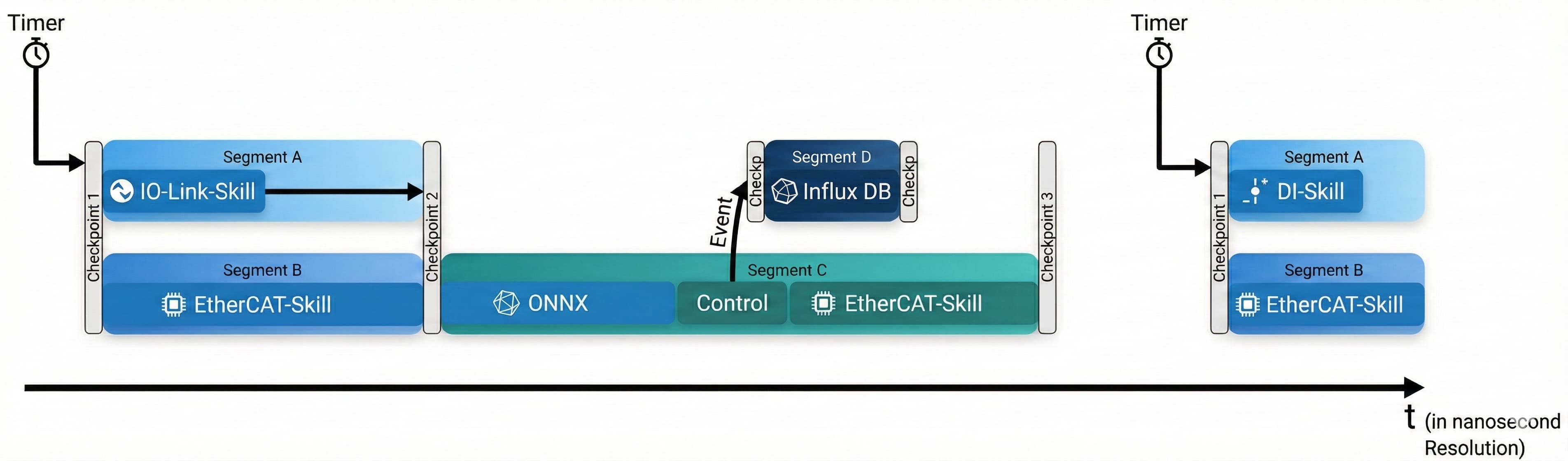

This technology's main innovation is the timing model, which coordinates the timing of data, skills, and microservices among CPU cores and possibly GPUs. DIN 44300 defines real-time as the predefined or modeled response times of processing systems.

In traditional OT systems, this is accomplished via a high-frequency "read-process-write" cycle. In Xentara, timers and events generate numerous triggers that run skills and microservices sequentially and concurrently. These "tracks" might be separate or coordinated.

Figure 1: A simple timing model for sequential and parallel processing

Xentara-based multicore edge controllers can cycle at up to 100 kHz with microsecond precision.

It is critical to coordinate data transmission with the underlying PLC—especially if Xentara takes over control logic. This enables conventional control logic and machine learning to work in tandem, allowing machines to become smarter and more adaptable to change.

When interacting with the cloud, data must be prepared differently to be sent as messages. Additional fieldbus interfaces (Connectors) allow for the integration of more sensors and devices, up to full production line integration.

In all of these circumstances, the timing model assures that components coordinate temporally.

Development.

Although PLC programming, machine learning, and skill improvement all demand separate skills, complexity increases only little due to modularity and standardized interfaces. The Xentara Inspector and Debugger, simulation models (FMI/FMU), and a testing framework all contribute to virtual development, commissioning, and validation. These IT methodologies accelerate development and greatly increase software quality throughout the machine's lifecycle.

IoT Readiness and Business Models.

"IoT Readiness" refers to a system that already delivers critical data such as OEE, energy usage, and fault management. However, it also requires effectively integrating this data into existing digitalization frameworks. This transforms the machine builder into a system integrator for the end user, providing access to vital data and facilitating the development of know-how. It also makes machines more competitive, allowing for much greater prices.

Customers, however, anticipate not just new equipment, but also retrofit kits for all previously delivered models. This necessitates the use of a standardized IoT-ready platform, such as Xentara, that seamlessly connects with the customer's digital infrastructure. This platform can also support other services, which are added through device management. This adaptability transforms a typical machine into a smartphone-like platform that allows clients to add and mix services.

One example is an Augmented Reality (AR) skill that provides whole new ways to operation and training, significantly simplifying machine handling. This paves the way for the development of an ever-expanding range of value-added services, as well as service-oriented payment structures.

Share this article

If you found this article helpful, please share it with your friends!